Radio Controlled Rocket Glider Kits

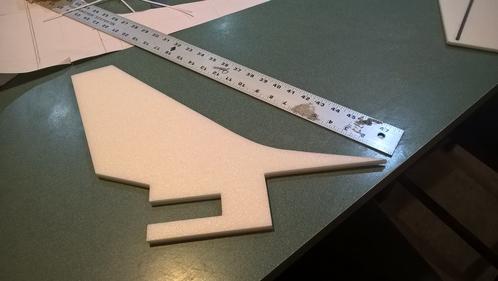

Model ready for painting

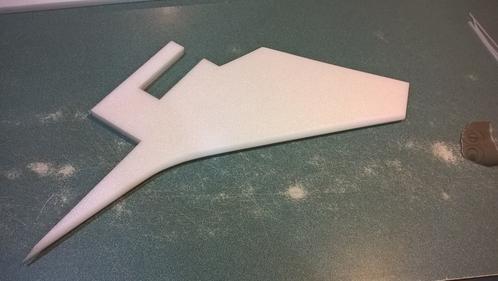

Wing control surfaces cut and hinged

Tail edges rounded.

Orion Starliner Large RC RG Plans:

This is a large model, 55" long, 3" diameter, and 37" wingspan. It is built light to fly on the low thrust G-12 rocket motor. Use of higher thrust motors may work but are not recommended since higher thrust put higher loads on the structure and give you less time to react to wind or trim issues.

Here is a plan for your personal use. Click on the link for a pdf download of the parts tracings. Use the pictures as references to how they go together. The link for instructions has the CG and locations for the pivot rod and tail/wing slots.

I use a slightly tail heavy launch condition and slightly nose heavy glide and it works without having to shift balast. You will need at least a 6' rail for launching, and this is designed to use the 32mm G-12 aerotech motor exclusively.

Reminder that this was scanned full size, but printers normally cannot print to the edges, and they will shrink the image and put some border around it, this will yield a smaller than original print and may cause mis-alignment, make sure you turn off page scaling in the printer before printing, and that there is no scaling or auto-expand or fill to the sheets and that you print without borders.

Build light, I've included carbon where it is needed for flight loads. I use velcro to hold the RX and bec/esc in place, as it allows easy changing out if needed.I don't use clevis connectors, but use .047 music wire and Z bends that fit tightly and glue my servos in place. Less to fail or go wrong. there is zero slop and it is light and simple. If you have to splice your foam sheets, use blenderm tape on both sides to reinforce the joint if needed. I use great planes or dubro wing skids on the bottom of the fuse and this helps avoid landing damage. Please feel free to send me feedback on any issues or success you have. Note this was designed to use 6mm depron sheet which has the perfect combination of stiffness and light weight. This may mean you need to adjust slots for a different thickness or add more carbon to provide the right stiffness if you use a different type/thickness of foam.

Tail pieces joined using 3m-77 spray adhesive.

Wing top added using 3m-77 spray adhesive

Motor mount tube glued in place.

Wing halves joined and grooved, spars glued into place

Servos and control horns intalled, hatch added for receiver/battery access

Wing edges rounded.